Medical Laser Solutions for OEMs in Healthcare:

Reliable, High-Quality Laser Solutions That Reduce Costs and Speed Innovation

-

-

High-performance lasers without breaking the bank – best value per Watt ($/W) from development through production

-

-

-

We’ll deliver the right laser solution for your program’s success – standard or customized to meet your exact specs

-

-

-

Thousands of units deployed in key medical applications – diagnostics, surgery, minimally invasive therapies & more

-

-

Start small or go big: streamlined OEM integration & scalable growth from laser diode components to pulsed laser systems

30 Years Helping Turn Ideas into Life-Changing Medical Systems

Show me Medical & Healthcare Laser Sources!

We partner with you to help tackle your toughest laser challenges

Medical laser hurdles slowing you down? RPMC can help:

- Rising Costs

Sourcing affordable, high-quality lasers is tough with increasing tariffs and prices - Laser Performance Needs

Finding a laser that meets your unique performance specs can be overwhelming - Product Obsolescence Risks

Vendor discontinuations and outdated lasers disrupt your medical device production - Time to Market Delays

Tight timelines & complex ISO 13485 certifications slow your medical device launch - Supply Chain Disruptions

Import delays and logistics snags make consistent laser supply a headache

We get your pain – RPMC simplifies these challenges with cost-effective, standard or custom lasers that meet your exact specifications, delivered fast & built to last your product’s lifecycle. Tell us about YOUR challenges:

Explore real-world Success Stories: RPMC’s solutions tackle medical challenges

Our laser solutions empower OEMs like you to achieve medical breakthroughs. We offer laser technology with a strong emphasis on IP protection, collaborative development, and responsiveness to your needs, providing end-to-end support as your dedicated partner – from laser selection to customization, certification adherence, integration, and ongoing technical expertise – ensuring you get the right solution for a successful product launch.

Our laser solutions power real medical advancements for OEMS like you:

Medical & Healthcare Success Stories

Offering the largest selection of standard & custom wavelengths & packaging on the market, RPMC excels at getting you the exact right solution. So, when a leading medical aesthetics company needed high-power laser diodes at unique, custom IR wavelengths for advanced skin resurfacing applications after their previous vendor discontinued production, RPMC was able to deliver custom developed IR multimode laser diodes with free-space output, enabling deep tissue penetration for precise skin rejuvenation. Our flexible design and US-based development supported their high-volume OEM production, providing a reliable and cost-effective, drop-in replacement with superior dollars-per-watt value, outperforming the prior vendor’s pricing.

Technical Specs: Custom IR wavelengths, high-power multimode, free-space output, compact package.

Outcome: Restored supply chain reliability, enhanced treatment precision, and reduced costs for OEM skin resurfacing systems.

RPMC specializes in finding the right standard or custom solution for your requirements. An OEM medical system developer had a lab-grade proof-of-concept laser system for novel vascular & ophthalmologic treatments, but sought a robust, field-deployable laser solution to take to market. RPMC delivered rugged, custom 1064 nm and 532 nm Wedge, Onda, and Sol lasers with nanosecond pulses, low jitter, and high pulse-to-pulse stability, ensuring precise tissue absorption and reliability in the field. Optimized for high-volume production and FDA-qualification, these laser solutions streamlined OEM integration and enabled precise, innovative treatments with highly repeatable performance for both cosmetic and life-saving therapies.

Technical Specs: 1064 nm and 532 nm, nanosecond pulses, low power, low-jitter, compact package.

Outcome: Reduced costs, increased quality, performance, reliability & serviceability, and streamlined production & FDA-qualification.

A leading ophthalmology laser specialist required cost-effective, yet higher power 808 nm laser diodes to pump YAG and YLF crystals for 532 nm and 577 nm laser output in retinal and glaucoma therapy applications. RPMC’s fiber-coupled laser diode module delivers 30 W, enabling efficient crystal pumping for precise ophthalmic treatments. With our 808 nm laser diodes being among the lowest cost 808 nm options on the market, we were able to deliver high-performance diodes, within the design budget, securing our position as the go-to vendor for all laser diode wavelength and power needs.

Technical Specs: 808 nm, 30 W, fiber-coupled, multimode, compact module.

Outcome: Powers high-precision retinal and glaucoma treatments, optimizing OEM production with cost-effective performance.

Stuck with limited commercial-off-the-shelf (COTS) diode options, a leading medical device innovator contacted RPMC, seeking significantly higher power near-infrared laser diodes for advanced endoscopic imaging in minimally invasive diagnostics, while maintaining a compact system footprint and staying within budget. RPMC’s multi-emitter laser diode at 810 nm delivers cost-effective high optical power in a compact C-mount package and enables deep tissue penetration with low scattering for enhanced visualization of vascular and cellular structures. The multi-emitter configuration incorporates multiple discrete emission regions on a single chip, providing elevated optical flux, improved signal-to-noise ratios, sharper resolution, and improved measurement reliability in low-light and spectrally complex environments. This solution provided higher optical output within a compact footprint, directly enhancing endoscopic imaging fidelity and diagnostic performance through superior signal quality.

Technical Specs: 810 nm, 10–20 W output, multi-emitter design, C-mount package

Outcome: Provided increased output power, maintaining system size and budget, while enhancing endoscopic imaging resolution and diagnostic accuracy

A leading innovator in cellular diagnostics required precise & stable pulsed illumination with high repetition rate at 1064 nm and 770 nm for a high-throughput flow cytometry system targeting immuno-oncology and rare cell analysis. RPMC’s Wedge XB DPSS laser delivers stable, nanosecond & sub-ns pulses with high repetition rates in a compact package, ensuring precise marker detection and reliable pulse-to-pulse consistency, crucial for single-cell analysis. The elegant triggering scheme supports advanced data acquisition methods, while high beam & pulse stability, minimal waste heat, and compact size help maintain system efficiency and reduce overall footprint. This solution enhances throughput and signal uniformity, supporting accelerated product development, clinical trial success, and high-volume OEM production.

Technical Specs: 1064 nm (<1 ns pulses), 770 nm (<3 ns pulses), 1 kHz PRF, compact design.

Outcome: Significantly improved signal uniformity and high-speed detection resolution, increasing throughput & reducing calibration downtime.

Another OEM ophthalmology system developer needed low-power 808 nm laser diodes for advanced glaucoma treatment using pulsed, direct illumination. RPMC’s IR free-space laser diode delivers 6 W in a compact TO-3 package with free-space output, enabling precise, modulated micropulse delivery for minimally invasive therapy at one of the most competitive 808 nm price points on the market. Tailored for FDA-compliant integration, its cost-effective dollars-per-watt value supports high-volume OEM production, ensuring reliable performance in clinical settings.

Technical Specs: 808 nm, 6 W, multimode, free-space TO-3 package.

Outcome: Enhances glaucoma treatment precision, streamlines OEM integration, and reduces costs with competitive pricing.

A global leader in dental laser technology required a versatile 940 nm laser diode for soft tissue ablation, teeth whitening, and pain therapy in a single system. RPMC’s custom 940 nm 10 W multimode laser diode, delivered with free-space output with a connector for customer fiber integration, offers high hemoglobin absorption and versatile output compatibility for multi-application precision. Its compact design ensures seamless integration, while superior dollars-per-watt value reduces costs for high-volume OEM manufacturing in a cost-sensitive market.

Technical Specs: 940 nm, 10 W, multimode, free-space with connector, compact package.

Outcome: Enables precise, multi-functional dental procedures, streamlines OEM integration, and reduces costs with competitive pricing.

RPMC has provided laser sources for many successful Medical & Healthcare applications:

Aesthetics

- Fractional Laser Therapy (non-ablative)

- Hair Removal

- Scar Reduction/Tattoo Removal

Ophthalmology

- Optical Coherence Tomography (OCT)

- Retinal/Corneal Procedures

- Glaucoma Management

Photodynamic Therapy (PDT)

- Cancer Treatment

- Dermatology – PDT

- Ophthalmology – PDT

Dental

- Soft Tissue Surgery

- Periodontal Treatment

- Teeth Whitening

Medical Marking

- Black Marking

- Device Labeling

- Implant Identification

Low-Level Laser Therapy (LLLT)

- Pain Management

- Wound Healing

- Anti-Inflammatory Treatments

Surgical

- Minimally Invasive Procedures

- Tissue Ablation

- Precision Cutting

Glass Marking/Processing

- Specialty glass marking

- Precision drilling

- Advanced cutting

Laser-Induced Thermal Therapy (LITT)

- Tumor Ablation

- Neurological Applications

- Targeted Tissue Heating

RPMC’s success is driven by our dedicated team & the invaluable support of our skilled & innovative manufacturers.

Explore our wide range of laser technology, powering those Medical Success Stories

From laser eye surgery to passivation resistant black marking on medical devices, we have a huge selection of OEM laser sources for medical laser manufacturers.

Whether you need a drop-in replacement or you’re developing an innovative new procedure, our diverse laser diodes, pulsed DPSS lasers & fiber lasers offer standard off-the-shelf solutions supporting ISO & FDA compliance.

Most products are highly configurable, delivering tailored performance for your medical device without the high cost of fully custom designs.

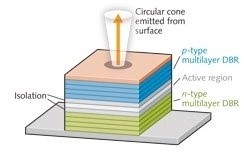

Laser Diodes: Standard & Configurable for Medical Applications

| Laser Type | Application |

|---|---|

| 760–810 nm Red Laser Diode Bars/Stacks & 1064 nm DPSS | Epilation/Laser Hair Reduction & Removal |

| UV–Red Laser Diodes in 9mm TO-Can with SMA Connector | Dental Applications |

| 810, 940 & 1940 nm Fiber-Coupled Laser Diodes | Oral & Soft Tissue Surgery |

| Pulsed, Low-Power 808 nm Laser Diodes | Glaucoma Treatment |

| High-Power Multi-Emitter 810 nm Laser Diodes | Endoscopic Imaging |

| Free-Space & Fiber-Coupled Laser Diodes (405–1300 nm) | Acne & Scar Removal |

| High-Power Multimode Custom IR Wavelength Laser Diodes | Skin Resurfacing |

| 808 nm Diode for 532/577 nm Output | Ophthalmic Therapies |

| Red & NIR Laser Diodes | Photodynamic Therapy (PDT) |

Best Value Per Watt:

Laser Diodes & CW Laser Modules deliver stable & reliable, value-packed Dollars/Watt performance for high-volume production and scalable growth.

Wavelength & Technology:

UV to SWIR, Single & Multimode, Wavelength-Stabilized, and DFB / VBG Narrow Linewidth / SLM options for your unique performance specifications

Flexible, Reliable OEM Integration:

Free-space & fiber-coupled, components to modules, and endless packaging flexibility, designed for the lifetime of your system

Budget-Friendly Custom Performance:

Configurable power, wavelength, linewidth, beam shaping, cooling, redundancies & more: customization w/out the ‘fully-custom’ price tag

Pulsed Lasers: Standard & Configurable for Medical Applications

| Laser Type | Application |

|---|---|

| Low Jitter ns-Pulsed 1064/532 nm DPSS | Vascular & Ophthalmologic Treatments |

| ns to ps Pulsed 532 nm & 1064 nm DPSS | Tattoo Removal |

| VIS-IR ps-Pulsed DPSS & IR fs-Fiber | Medical Device Black Marking |

| 1030 nm Femtosecond Fiber Lasers | Glass Processing |

| Broadband Tunable ps-Pulsed Supercontinuum Lasers | Optical Coherence Tomography (OCT) |

| Nano- & Sub-ns Pulsed 1064 & 770 nm DPSS | Flow Cytometry/Cellular Diagnostics |

High-Quality Pulsed Performance:

Nanosecond, Picosecond & Femtosecond: provide high pulse energy/peak power & high-quality beams for precise focus & targeting

Many Wavelengths & Tunable Options:

Fundamental & harmonics produce UV – SWIR, tunable options to access any wavelength using supercontinuum & OPO technologies

Dynamic Laser Characteristics:

Flexible platforms allow configurable pulse width, rep. rate, pulse energies, and beam delivery options for your tailored solution

Peak Power Pulsed Capabilities:

From permanent black marking to efficient tissue ablation to glass processing, our high peak power pulsed options deliver results

Custom Medical OEM Laser Solutions:

Wafers to Components to Complete Laser Systems

Despite offering > 10,000 standard products, often a custom solution is required. Our expert manufacturing partners collaborate directly with you and their engineers to tackle design challenges, meet precise specifications, and streamline development, delivering fully custom designs.

Learn More About RPMC’s Customization Capabilities

See why OEMs trust RPMC for their medical laser success

RPMC at a Glance:

-

30 years’ experience

10,000+ standard lasers

1000s of proven units fielded

Industry-leading laser sources

Endless customization options

Personalized support

Flexible & agile – no red tape

US-Made options

Buffer stock

Just-in-time deliveries “RPMC helped get our system off the ground, from a prototype to a market leader!”

~YOUR Name Here (IF you Contact Us!)

Small Enough to Care, Big Enough to Deliver

30 years providing medical laser solutions for OEMs in healthcare from prototypes to high-volume medical laser production. Our expert team, backed by top-tier manufacturing partnerships, guides you from selecting precise low-jitter pulsed lasers for ophthalmology or high-power diodes for epilation to ensuring market-ready devices.

Even if we’re new to your system, we simplify complex challenges like regulatory and supply chain hurdles, delivering proven lasers that match your vision and are available for the lifetime of your project.

As a flexible, agile small business, we offer responsive support and, when no standard solution is available, collaborate directly with our manufacturers’ engineers to craft high-impact, tailored solutions—leveraging partnerships, U.S.-made options, and just-in-time delivery to reduce tariff burdens and keep your project on track.

RPMC is your go-to partner for medical laser solutions that drive breakthroughs to make your next healthcare project a success!

BUY NOW

BUY NOW