Industrial Laser Solutions for OEMs & Manufacturers:

Robust, Versatile Laser Solutions for Harsh Environments & High-Throughput Production

-

-

Ruggedized lasers for harsh industrial conditions – reliable 24/7 performance in humidity, heat, dust & vibration

-

-

-

Versatile power, energy & wavelengths – tailored for diverse application requirements from precision to high-volume tasks

-

-

-

Thousands of units deployed in key industrial apps – material processing, analysis, sensing, marking, joining & more

-

-

Seamless OEM integration & scalable systems – from components to turnkey, customizable for your production needs

30 Years Driving Industrial Innovation & Efficiency with Reliable Laser Solutions

Show me Industrial & Manufacturing Laser Sources!

Tackle your toughest industrial & manufacturing challenges with RPMC’s expertise:

Struggling with laser challenges in your manufacturing process? RPMC can help:

- Rising Costs

High laser prices and tariffs strain production budgets, making cost-effective solutions critical - Downtime & Reliability Issues

Unreliable lasers cause costly production delays in harsh environments like factories or mines - Complex Integration Needs

It’s hard to find the ideal laser source & specifications that’s also easy to integrate with your design - Supply Chain & Availability Issues

Long lead times, supply chain disruptions & product availability issues disrupt tight schedules - Demanding Performance Standards

Achieving precision, high throughput & quality with a laser that fits your needs within your budget

We get your pain – RPMC tackles these challenges with rugged, customizable lasers thaat boost uptime, streamline integration, and deliver superior performance at competitive costs. Tell us about YOUR challenges:

Explore real-world Success Stories: RPMC’s solutions solve industrial challenges

RPMC empowers industrial OEMs and manufacturers with rugged, reliable laser solutions tailored to your toughest challenges. Our 30 years of expertise ensure seamless collaboration, from selecting the right laser to customizing for unique specs, environments, high-precision, or high-throughput needs. We prioritize reliability, cost savings, and quick integration, delivering field-proven systems that boost uptime and quality. With thousands of units deployed, our end-to-end support—backed by technical guidance and rapid response—drives your production success.

Our laser solutions power real industrial applications for companies like yours:

Industrial & Manufacturing Success Stories

A national laboratory needed UV lasers for a sensitive application involving a magnetic chamber but faced challenges ensuring compatibility with the environment. Their initial inquiry outlined basic needs, but lacked specifics. RPMC engaged early, collaborating through calls and emails with their team and our manufacturer to clarify requirements. We identified a fiber-coupled UV laser solution, tailored to withstand the chamber’s magnetic conditions while delivering reliable performance. This collaborative process ensured seamless integration, meeting their stringent demands and enabling successful deployment in their specialized system. RPMC’s responsive support and tailored solution provided the lab with a dependable, high-performance laser system.

Laser Solution: Fiber-coupled UV laser designed for a specialized magnetic chamber application

Outcome: Enabled reliable operation in a challenging environment, supporting successful project execution

A leading global laser manufacturer faced challenges sourcing a pump laser diode for a new industrial laser system. Their project demanded a specific wavelength, linewidth, and reliable high-power output, all within strict performance and cost constraints. Engaging RPMC early, they shared critical requirements for reliability and scalability. Our team collaborated closely with their engineers, leveraging our extensive manufacturer network to identify the ideal partner. We delivered a tailored open heatsink IR laser diode, customized to meet their exact wavelength and power needs. This solution streamlined integration, ensured consistent performance, and met budget expectations, enabling a successful system launch. RPMC has reliably supplied this pump laser for over five years, supporting their high-volume production and ongoing innovation.

Laser Solution: Open heatsink IR laser diode with high power output for a specialized industrial laser system.

Outcome: Enabled streamlined integration, met cost and performance goals, and supported five years of reliable production.

A long-term RPMC partner needed a laser source for a new industrial project but was unsure of the ideal solution. Facing tight development timelines and specific performance demands—like precise beam control in challenging environments—they engaged RPMC early. Our team worked closely with their engineers, analyzing key requirements for reliability and integration ease. Drawing on our extensive manufacturer network, we identified and delivered a tailored IR lensed free-space multimode laser diode, customized for their unique needs. This collaborative approach ensured streamlined integration, accelerating their development and enabling a successful product launch.

Laser Solution: IR lensed laser diode with custom beam shaping for a specialized industrial application

Outcome: Reduced development time, ensured reliable performance, and supported successful market entry.

A U.S. transportation company developing a system to detect road hazards, like potholes, needed a laser solution but lacked in-house expertise. They approached RPMC for a turnkey system to demonstrate their concept. Our team collaborated closely, delivering a fiber-coupled laser diode with optics and line generation to showcase their system’s capabilities. After successful demonstrations, they sought a production-ready OEM solution. We provided a compact, cost-effective package with a fiber-coupled laser diode, temperature controller, and independent driver, optimized for high-volume production. This streamlined integration, reduced costs, and met their space constraints, enabling a successful transition to market.

Laser Solution: Fiber-coupled laser diode with line generation, compact OEM components for road hazard detection

Outcome: Facilitated rapid demo deployment, cost-effective production & reliable market deployment

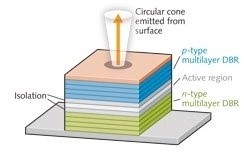

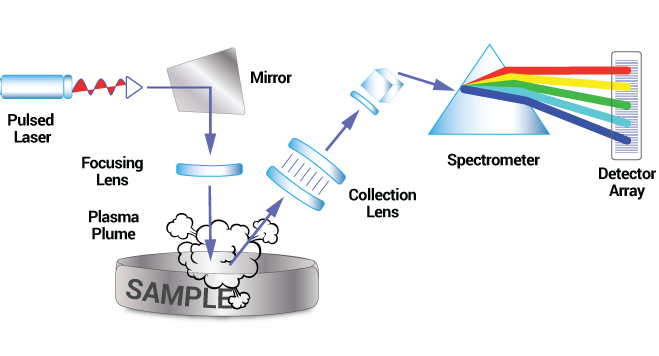

A mining industry innovator needed a laser solution for laser-induced breakdown spectroscopy (LIBS) to analyze material composition via plasma plumes. Their existing lasers were bulky, underperformed, and overpriced, hindering efficient, high-throughput analysis in rugged mine environments. They turned to RPMC for a better fit. Our team collaborated closely with their engineers to understand their need for compact, high-performance lasers. We delivered a tailored pulsed laser solution optimized for high repetition rates, enabling faster material analysis. The compact design and robust performance met their demands, seamlessly integrating into their LIBS system and boosting operational efficiency. RPMC’s solution outperformed their previous setup, ensuring satisfaction in size, performance, and cost.

Laser Solution: High-repetition-rate pulsed laser for a high-throughput LIBS application in mining

Outcome: Improved analysis speed and reliability, enhancing throughput in rugged mining operations

A leading manufacturer developing a commercial product for transient absorption spectroscopy needed robust laser sources to meet demanding performance requirements. They struggled to find reliable lasers with specific wavelengths for their industrial application. Early in development, they partnered with RPMC, sharing their needs for durability and precise wavelength flexibility. Our team collaborated closely with their engineers, leveraging our extensive manufacturer network to select the ideal solution provider for their project. We delivered rugged pulsed lasers, customized for their unique wavelength and stability needs. This tailored solution ensured seamless integration, zero performance issues, and supported their commercial product launch. RPMC’s reliable supply has sustained their production for over six years, driving ongoing success.

Laser Solution: Rugged pulsed lasers with tailored wavelengths for specialized industrial spectroscopy

Outcome: Enabled reliable production with no downtime supporting market success for over six years

RPMC has provided laser sources for many successful Industrial & Manufacturing applications:

RPMC’s success is driven by our dedicated team & the invaluable support of our skilled & innovative manufacturers.

Explore our wide range of laser technology, powering those Industrial Success Stories

RPMC’s curated selection of rugged, versatile lasers powers your manufacturing operations – precision micromachining to high-throughput sensing – saving you time & money w/ reliable performance in harsh environments.

Our diverse portfolio includes everything from fiber-coupled laser diodes to pulsed DPSS & ultrafast fiber lasers, optical amplifiers & more, designed for streamlined integration with OEM devices or in your manufacturing process.

Explore these diverse industrial laser options below, matched to key industrial applications, each with configurable and customizable options for power, wavelength, pulse characteristics, and more, tailored for your exact needs.

| Application Group | Application | Supporting Laser Categories |

|---|---|---|

| Material Processing & Surface Modification |

|

|

| Display & Electronics Manufacturing |

|

|

| Sensing, Measurement & Characterization |

|

|

| Joining Processes |

|

|

| Communication & Data Transmission |

|

Custom Industrial OEM Laser Solutions:

Wafers to Components to Complete Laser Systems

Despite offering > 10,000 standard products, often a custom solution is required. Our expert manufacturing partners collaborate directly with you and their engineers to tackle design challenges, meet precise specifications, and streamline development, delivering fully custom designs.

Tailored Laser Solutions for:

• Industrial laser machinery • Laser marking/etching/engraving • Wire stripping & paint removal • Micropatterning & LIPSS • Ultrafast laser cutting of glass • Laser welding copper/non-ferrous metals • Percussion drilling / Glass vias drilling • Laser sensing & measurement •

Learn More About RPMC’s Customization Capabilities

See why OEMs trust RPMC for their industrial laser success

RPMC at a Glance:

-

30 years’ experience

10,000+ standard lasers

1000s of proven units fielded

Industry-leading laser sources

Endless customization options

Personalized support

Flexible & agile – no red tape

US-Made options

Buffer stock

Just-in-time deliveries “RPMC provided a reliable, tailored laser for our high-throughput industrial solution!”

~YOUR Name Here (IF you Contact Us!)

Small Enough to Care, Big Enough to Deliver

For 30 years, RPMC has delivered rugged, reliable laser solutions for industrial OEMs, from proof-of-concept development to high-volume manufacturing. Our expert team, backed by top-tier manufacturing partnerships, guides you from selecting high-energy pulsed lasers for material processing to robust diodes for joining, ensuring seamless integration in demanding environments.

We simplify complex industrial challenges like downtime, supply chain delays, and custom specs, delivering proven lasers that enhance throughput, quality, and reliability for the lifetime of your project.

As a flexible, agile small business, we provide responsive support and collaborate with our manufacturers’ engineers to craft tailored solutions—leveraging U.S.-made options, buffer stock, and just-in-time delivery to minimize costs and keep your production on track.

RPMC is your go-to partner for industrial and manufacturing laser solutions that reduce costs, improve quality, and increase throughput!

BUY NOW

BUY NOW