Defense & Aerospace Laser Solutions for Mission-Critical Applications:

Rugged Lasers Delivering Precision & Reliability in Harsh Environments

-

-

Field-Proven Ruggedness – Built to perform in harsh environments, designed to withstand shock, vibration, thermal extremes, and humidity

-

-

-

Low SWaP Optimization – Compact, lightweight designs that fit handheld, vehicle-mounted, UAV, and airborne platforms, maintaining performance

-

-

-

“Eye-Safe” & Tactical Wavelengths – 1.5 µm and SWIR options for safety and clear atmospheric transmission + UV-LWIR for specialized applications

-

-

Thousands of Units Fielded – Proven track record in DoD programs, with qualifiable solutions, backed by full support throughout the process

30 Years Enabling Critical Programs for Defense & Aerospace with Field-Proven Laser Sources

Show me Defense & Aerospace Laser Sources!

Tackle your defense challenges with RPMC’s expertise & mission-ready lasers:

Navigating the Toughest Defense & Aerospace Laser Challenges

Six-month schedule slip on a custom module? Beam dies at 40°C? RPMC can help:

- ITAR & Export Nightmares

Sensitive data, endless paperwork & disappearing vendors when compliance questions arise, causing delays - Schedule-Killing Lead Times

Big suppliers quote 18-24 months for “Custom” – program office needs hardware for the approaching PDR - ‘Impossible’ Low SWaP Specs

Ex: High pulse energy at ‘eye-safe’ 1.5µm in a robust, compact package w/ extended operating temp. range - Qualification Hell

Meeting MIL-STD-810H, STANAG, EMI & more – maintaining peak performance in harsh conditions - Spec Creep & Big Company Bureaucracy

Requirements change every review cycle – large laser companies may ignore unless it’s a massive order

We get your pain – we work with the same primes and agencies you do. RPMC delivers battle-tested, U.S.-supported solutions with the flexibility larger firms often lack: rapid prototypes, configurable & fully tailored solutions, and direct access to the manufacturer’s engineering team.

Tell us about YOUR challenges – we’ve likely solved something similar already:

Explore real-world Success Stories:

How RPMC’s lasers support critical missions in the field

Real-World Success:

Laser Solutions for Defense & Aerospace Applications

With 30 years of experience, RPMC supports defense primes, integrators, and program managers – from DoD agencies to Tier-1 contractors – with rugged, qualifiable laser solutions built for your toughest missions. We collaborate closely with you and our engineers, from choosing eye-safe wavelengths to customizing for low SWaP, shock/vibration, or extreme thermal conditions. We prioritize maintaining your tight timelines, controlling costs, and ensuring high reliability, providing proven laser sources that perform in real operations. With thousands of units fielded in rangefinders, DIRCM, HEL demonstrators, and FSOC systems across North American programs, our flexibility, end-to-end support, direct manufacturer access, and rapid response times help turn RFPs into successfully deployed systems.

Here’s how our lasers have supported programs like yours in the field:

Defense & Aerospace Success Stories

Programs upgrading their rangefinding or precision-guidance modules often struggle to achieve higher ‘eye-safe’ peak power and stronger return signals than 905 nm diodes can provide. After discussing their performance and SWaP constraints with RPMC’s technical team, system designers evaluated triple-junction 1550 nm pulsed diodes, offering higher efficiency and improved return strength in haze, dust, and maritime environments. This allows extended detection ranges and better accuracy, with greatly increased output power and only a minimal increase in power consumption or thermal load.

Laser Solution: High peak power, “eye-safe” 1550 nm multi-junction pulsed diode for LRF/targeting/guidance systems

Outcome: Stronger return signals in degraded visibility and extended effective operating range within existing SWaP constraints

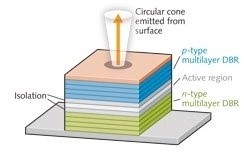

LEO constellation designers required reliable free-space optical communication to support high-throughput, low-latency links between satellites. Their challenge was achieving sufficient optical gain and modulation bandwidth in a compact, radiation-resilient package. After evaluating link budget requirements with RPMC’s technical experts, they adopted high-gain 1550 nm semiconductor optical amplifiers, which provide strong single-mode amplification and high saturation power for robust inter-satellite links.

Laser Solution: Compact, high saturation power, high-gain single-mode 1550 nm SOA for FSOC sat comms

Outcome: Reliable, high-speed optical links with enhanced resistance to interception, improving overall constellation connectivity

CubeSat and small-sat programs increasingly rely on pulsed LIDAR for proximity awareness and debris avoidance, but most commercial lasers are too large or thermally unstable for tight spaceborne SWaP constraints. By defining their pulse-energy, packaging, and vacuum constraints in collaboration with RPMC’s team, they identified a 1550 nm nanosecond pulsed fiber laser that offered stable, eye-safe output in a compact hermetic design suited for LEO thermal cycling.

Laser Solution: Compact, high-power, 1.5 µm nanosecond pulsed fiber laser, hermetic design for small-sat missions

Outcome: Accurate telemetry and obstacle detection to support safer autonomous CubeSat navigation

Teams developing next-generation LIDAR mapping payloads needed a compact, rugged 532 nm source that maintained pulse energy and stability through vibration, temperature swings, and high-altitude duty cycles. Their previous laser drifted thermally and produced inconsistent returns over water and vegetation. By reviewing the requirements with RPMC’s team, they identified a nanosecond 532 nm DPSS platform, such as our Aero Series of high-energy lasers, delivering the stable pule-to-pulse energy needed for reliable multi-return bathymetry and terrain profiling.

Laser Solution: High-energy, conduction-cooled, nanosecond pulsed 532 nm DPSS laser for airborne sensing

Outcome: More consistent foliage and water returns, improved waveform stability, and reliable data quality under representative flight conditions

Developers of IR countermeasures and seeker-testing equipment needed to replace bulky lamp or OPO sources that limited modulation speed and introduced SWaP challenges. After reviewing wavelength, modulation, and thermal constraints with RPMC’s specialists, they transitioned to compact mid-IR quantum cascade lasers, providing >1 W average output per chip and fast modulation capabilities in a small HHL package. This enabled lighter, more agile countermeasure prototypes and simplified thermal and mechanical design.

Laser Solution: Compact, high-power, fast-modulating mid-IR QCLs for IRCM/DIRCM development

Outcome: Reduced system size, thermal requirements, and improved waveform agility for modern mid-IR countermeasure testing & simulation

Teams modernizing their low-light imaging suites needed a SWIR illuminator that matched the sensitivity of new InGaAs cameras while reducing signature in the visible and near-IR bands. Older illuminators often produced bloom, spectral leakage, or insufficient irradiance at operational ranges. Working with RPMC to refine their illumination and spectral requirements, they selected high-power SWIR multimode diodes, available in free-space and fiber-coupled formats in the LDX-SWIR series, providing compact, spectrally aligned output for long-range contrast and recognition.

Laser Solution: Compact, high-power & brightness, SWIR CW laser diode for covert illumination and long-range imaging

Outcome: Improved identification performance with modern SWIR sensors and reduced visibility to legacy NIR/visible detectors

RPMC has provided laser sources for many successful Defense & Aerospace projects:

RPMC’s success is driven by our dedicated team & the invaluable support of our skilled & innovative manufacturers.

Explore our wide range of laser technology, powering those Defense & Aerospace successes:

Key Laser Products for Your Mission-Critical Needs

RPMC’s battle-tested portfolio of precision lasers drives your next program milestone – from handheld targeting pods to orbital HEL demonstrators – ensuring reliable performance in extreme environments where failure isn’t an option.

Our ruggedized lineup spans “eye-safe” multimode diodes to multi-kW fiber systems, pump modules, wavelength combiners, and compact amplifiers, all engineered for seamless integration into your tactical platform, airborne system, or secure comms terminal.

Dive into the defense laser groups below, each tied to core defense & aerospace applications, with built-to-spec options for wavelength, pulse energy, beam quality, and low SWaP optimization – locked in to meet your RFP requirements down to the last MIL-STD.

| Application Group | Application | Supporting Laser Categories |

|---|---|---|

| Remote Sensing & Imaging |

|

|

| Space-Based Applications |

|

|

| Targeting & Ranging |

|

|

| Laser Illuminators |

|

|

| Laser Communication & Data Links |

|

Custom Defense & Aerospace Laser Solutions:

Wafers to Components, Modules, Prototypes & Ruggedized Systems

Despite providing > 10,000 standard SKUs, your next program milestone often requires a built-to-spec solution. Our world-class partners will collaborate with you to define specifications and help you get the exact laser source your project requires, customized for the rigorous demands of your mission profile.

Tailored Laser Solutions for:

• “Eye-Safe” Rangefinding & Precision Designation • Directed Energy & HEL Weapon Systems • DIRCM & IRCM Countermeasures • Free-Space Optical Comms & Secure Links • Airborne LIDAR & Bathymetric Mapping • Tactical Dazzlers & Anti-Sensor Blinding • Space-Based Sensing & Beam Steering • Laser Guidance & Threat Detection •

Learn More About RPMC’s Customization Capabilities

See why integrators trust RPMC for their next program win:

RPMC is a Leading Supplier for Your

Defense & Aerospace Laser Solutions

RPMC at a Glance:

-

30 years serving defense programs

10,000+ standard laser configurations

1000s of units fielded in N. America

Battle-tested laser sources

Built-to-spec customization options

Personalized, direct technical support

Flexible & agile – minimal bureaucracy

US-origin & MIL-Spec options

Buffer stock for program surges

On-time deliveries amid tight schedules “RPMC delivered the rugged laser we needed to hit our milestone on time – zero failures in quality testing!”

~YOUR Name Here (IF you Contact Us!)

Small Enough to Care, Big Enough to Deliver

For over 30 years, RPMC has powered everything from tactical rangefinders to space-based HEL systems for North America’s leading primes, integrators, and government agencies. Our defense-experienced team, backed by top-tier manufacturer partners, guides you from wavelength selection to full SWaP-C optimization, with modular laser solutions that integrate seamlessly into your platform or prototype.

We tackle common defense hurdles, providing rugged, configurable lasers that meet your cost targets, engineered with the exact specs for extreme performance, reliability, and compliance – no matter the mission profile.

As a responsive, agile U.S. small business, we offer expert guidance, rapid quotes for RFPs, and direct access to factory engineers for streamlined collaboration, helping you navigate spec creep, export controls, and long cycles to keep your programs on track.

RPMC is your trusted laser partner for mission overmatch.

BUY NOW

BUY NOW