Laser micromachining has become a powerful tool in the fight against counterfeiting, enabling the embedding of microscopic 2D barcodes (data matrix codes) on items like medical devices, microelectronics, and precious metals. For professionals seeking high-precision micromachining systems, selecting the right laser is critical for achieving invisible, high-resolution markings. This article explores laser micromachining for anti-counterfeiting and outlines key considerations for choosing the ideal system, highlighting RPMC Lasers’ MicroMake micromachining system for superior performance.

Understanding Laser Micromachining for Anti-Counterfeiting

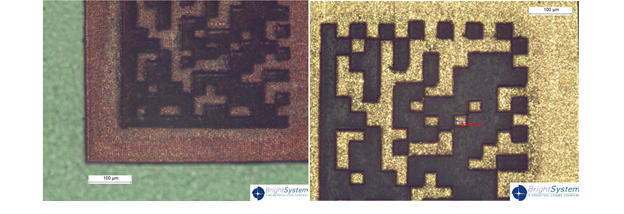

Laser micromachining embeds microscopic 2D barcodes (e.g., 400 µm x 400 µm) onto surfaces, invisible to the naked eye but readable under a microscope, ensuring robust anti-counterfeiting for high-value items. Sub-nanosecond pulsed Nd:YAG lasers at 532 nm or 266 nm deliver the precision and power needed for marking, cutting, drilling, and thin film removal on diverse materials like metals, ceramics, and transparent substrates. The MicroMake system integrates a compact laser, live microscope, and user-friendly software, making it ideal for these applications.

Key Considerations for Choosing Micromachining Lasers

Selecting a micromachining laser for anti-counterfeiting requires balancing wavelength, peak power, resolution, and system integration. Below are the primary factors to consider:

1. Wavelength Selection for Material Compatibility

The choice of wavelength depends on the target material. The 532 nm wavelength excels at micromachining metals and ceramics, while 266 nm is ideal for transparent substrates like glass, crystals, and polymers due to its efficient optical absorption and high resolution (~2–3 µm).

RPMC Solution: The MicroMake 266 and MicroMake 266 Plus offer 266 nm for transparent substrates, while the MicroMake 532 and MicroMake 532 Plus provide 532 nm for versatile material processing.

2. Peak Power and Pulse Repetition Rate

High peak power (up to 40 kW) and adjustable repetition rates (1–100 kHz) ensure efficient material ablation with minimal thermal damage, critical for creating precise 2D barcodes. Higher repetition rates enhance processing speed, while lower rates suit delicate substrates.

RPMC Solution: The MicroMake 532 Plus delivers >40 kW peak power at 10–100 kHz, while the MicroMake 266 offers >0.7 kW at 1 kHz for high-resolution marking.

3. Resolution and Precision for Microscopic Markings

Anti-counterfeiting requires high-resolution markings (2–5 µm) to embed intricate 2D barcodes. A 10x microscope objective and integrated live microscope enable precise alignment and in-process quality checks.

RPMC Solution: The MicroMake series achieves resolutions as low as 2.5 µm (266 nm) and 4.5 µm (532 nm), with a live microscope for real-time monitoring.

4. Integrated and Compact Design

A compact, all-in-one system simplifies setup and operation in lab or OEM environments. Features like user-friendly software and optional motorized stages enhance flexibility for applications like microcoding and thin film removal.

RPMC Solution: The MicroMake system integrates a laser, microscope, and software in a monolithic, air-cooled design, with optional XYZ stages for precise positioning.

5. Versatility for Diverse Applications

The MicroMake series excels in anti-counterfeiting and beyond, supporting applications like surface texturing, track interruption on PCBs, microcoding, thin film removal, and microdrilling across industries. For medical devices, the system enables permanent, passivation-resistant black marking, creating high-contrast, corrosion-resistant 2D barcodes (e.g., 400 µm x 400 µm) that withstand sterilization and passivation processes. This ensures durable, traceable identification for implants and surgical tools, meeting stringent regulatory requirements. The system’s flexibility makes it a scalable solution for microelectronics, displays, and biomedical applications.

RPMC Solution: The MicroMake series supports microcoding, thin film removal, and microdrilling on metals, ceramics, and dielectrics, with specialized capabilities for permanent black marking on medical devices, ensuring precision and durability.

Why Choose RPMC’s MicroMake for Anti-Counterfeiting?

The MicroMake micromachining system from Bright System, offered by RPMC Lasers, delivers unmatched precision for anti-counterfeiting 2D barcode marking. Available in MicroMake 266 (>0.7 kW, 1 kHz), MicroMake 266 Plus (>7 kW, 10–50 kHz), MicroMake 532 (>10 kW, 1 kHz), and MicroMake 532 Plus (>40 kW, 10–100 kHz), it supports a range of materials and applications. With a compact design, live microscope, and customizable options like motorized stages and Class 1 safety enclosures, MicroMake ensures high-quality results for microelectronics, medical devices, and more.

Ready to Select Your Micromachining Laser?

Choosing the right laser for anti-counterfeiting ensures precise, reliable 2D barcode marking. RPMC’s MicroMake system offers tailored solutions at 266 nm and 532 nm for your micromachining needs. Contact our team at info@rpmclasers.com or click below to explore your options.

Have questions?

BUY NOW

BUY NOW