Joining Process Lasers:

High Energy for Joining Applications like Welding, Cladding, Brazing, and Soldering

-

-

-

-

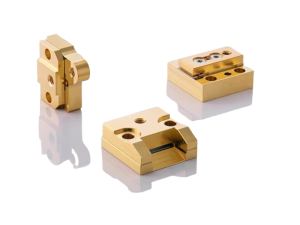

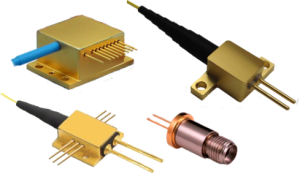

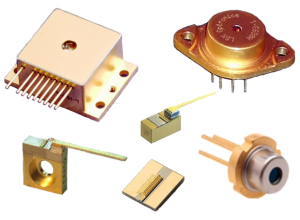

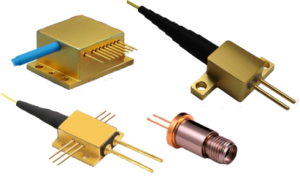

- Versatile Laser Diode Configurations for Precision Laser Joining

-

-

-

-

-

-

-

- Optimized Performance for High-Quality Joining Applications

-

-

-

-

-

-

-

- Reliable, Industrial-Grade Solutions Tailored for Diverse Environments

-

-

-

Why Choose RPMC for Joining Process Lasers?

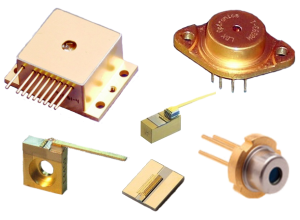

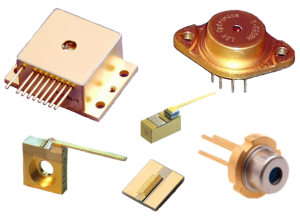

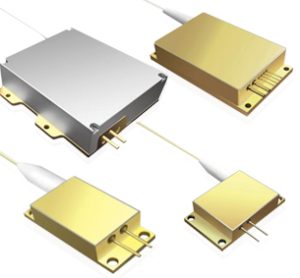

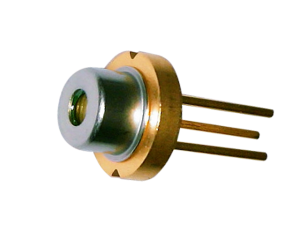

Versatile Laser Diode Configurations for Precision Laser Joining

-

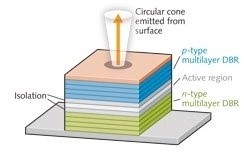

- Fiber-coupled & free-space, single & multimode for varied materials & joint types

- Single emitter, arrays (bars) & laser diode stacks from mW to kW-range

- From compact TO-can packages to OEM modules to turnkey systems

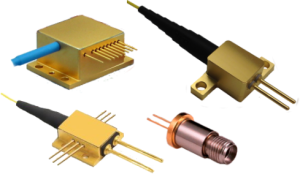

Optimized Performance for High-Quality Joining Applications

-

- High-power laser diodes deliver controlled heat for cladding, welding, brazing, and soldering

- Reduced HAZ & precise energy distribution enable superior joint strength and quality

- Adjustable power, UV-SWIR wavelengths & custom configurations to meet your needs

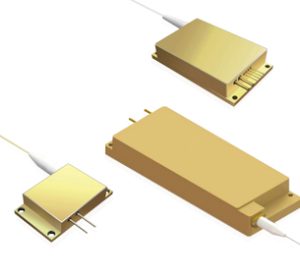

Reliable, Industrial-Grade Solutions Tailored for Diverse Environments

-

- Durable designs w/ rugged, field-proven components & high-volume production capabilities

- Flexible cooling and beam delivery options for seamless adaptation to different setups

- Made in the USA options and customizable platforms for reliable, precision joining

Over the last 30 years, RPMC has fielded thousands of joining lasers, built to endure the toughest conditions, delivering reliable performance from the shop floor to outdoor environments. Designed to withstand humidity, heat, dust, and vibration, these lasers provide consistent output with low maintenance, ensuring your operations run smoothly. With a versatile range of power, energy, and wavelength options, our lasers can be tailored to meet the specific demands of your application, from precision tasks to high-power throughput. We’re not just providing a product—we’re partnering with you to find the perfect solution and support you through every stage of your project, dedicated to helping you achieve long-term success.

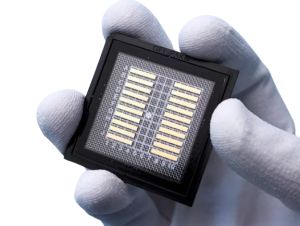

RPMC’s Joining Process Lasers offer advanced capabilities for welding, cladding, brazing, and soldering across automotive, aerospace, electronics, and medical industries. With a range of fiber-coupled and free-space configurations, these high-power CW lasers provide the precise heat control essential for quality joins with minimal heat-affected zones. Available in single emitter, array, and multi-emitter formats, our lasers enable strong, reliable bonds on varied materials, improving production efficiency and final product integrity. From compact modules to complete turnkey systems, RPMC’s lasers are built to meet the demands of industrial joining applications, ensuring dependable performance and robust operation in challenging environments.

Joining Process Laser Applications

Cladding/Deposition Lasers: Laser cladding (typically 808, 9XX, or 1064nm, multimode, high-power diode bar or stack) is a material processing technique in which a small amount of material is added to the surface of another material in a controlled manner. Typically, this is done in one of two ways either by blowing a focused jet of powdered material in a buffer gas coincident with the cladding laser spot or by depositing the material on the surface first and then scanning over it with the cladding laser.

Welding Lasers: In laser welding, the goal is to use the high-power long pulse lasers with a flat top beam profile to melt the material and fuse together each piece. The laser beam is typically focused onto the joint between the two parts along with an unfocused cover gas, whose primary objective is to prevent oxidation. Unlike cutting lasers, welding lasers (typically high-power diode bars or stacks) do not to remove material through ablation, utilizing lower powers and larger spot sizes.

Brazing Lasers: Brazing involves joining two or more materials by melting a filler material that has a lower melting point than the base materials. These lasers provide precise control over the heat input, allowing for localized melting of the filler material without excessively heating the base materials. This results in strong joints with minimal distortion and excellent aesthetics.

Soldering Lasers: Soldering is a process where a filler material, known as solder, is melted to join two or more components together. These lasers offer advantages in soldering applications by providing rapid, controlled heating of the solder and the workpieces. This leads to reliable and high-quality solder joints, particularly in applications requiring fine-scale connections or in areas with restricted accessibility.

Let Us Help

With 1000s of fielded units, and over 25 years of experience, providing OEMs, contract manufacturers, and researchers with the best laser solution for their application, our expert team is ready to help! Working with RPMC ensures you are getting trusted advice from our knowledgeable and technical staff on a wide range of laser products. RPMC and our manufacturers are willing and able to provide custom solutions for your unique application.

If you have any questions, or if you would like some assistance please contact us. Furthermore, you can email us at info@rpmclasers.com to talk to a knowledgeable Product Manager.

Check out our Online Store: This page contains In-Stock products and an ever-changing assortment of various types of new lasers at marked-down/discount prices.

BUY NOW

BUY NOW